From the rudimentary rulers of ancient civilizations to the sophisticated lasers and software of today, the world of metrology – the science of measurement – has experienced rapid evolution. This change has been powered by an insatiable need for accuracy and precision in various sectors, from manufacturing to space research. The advancements in metrology tools have made it possible to measure at micrometer levels and even beyond, thus making previously unimaginable feats possible. Let’s take a journey beyond the ruler to understand these incredible technologies that have shaped modern metrology.

Lasers: Lighting the Path to Precision

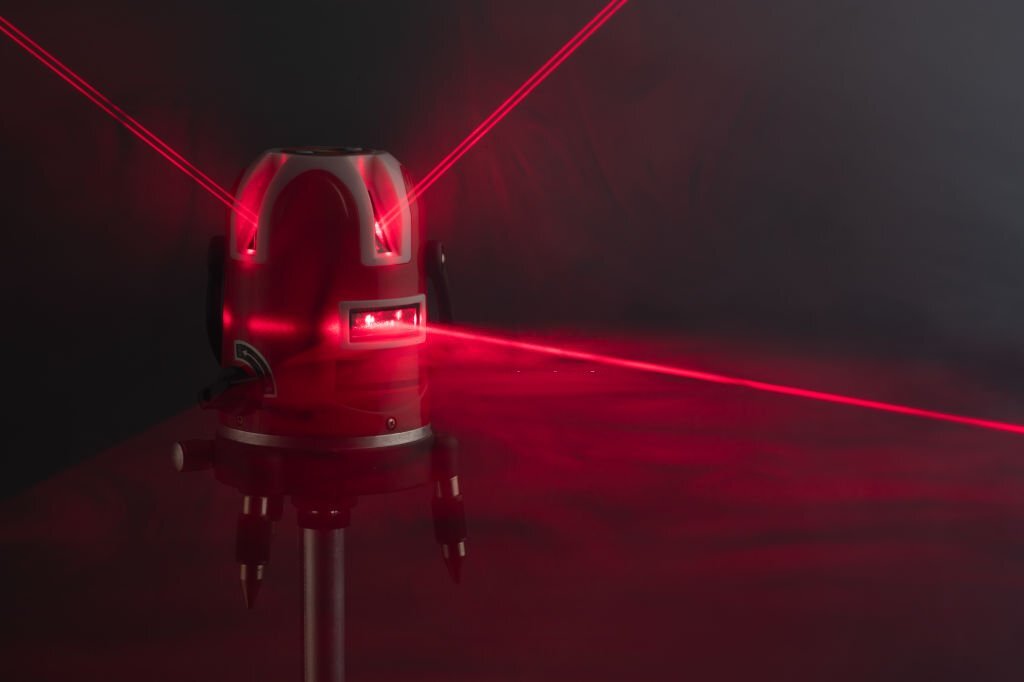

Long gone are the days when physical touch was a requirement for measurement. With the introduction of lasers in metrology, non-contact measurement became a reality. Lasers, due to their consistent wavelength and straight propagation, have become indispensable in modern metrology. Here’s how they transformed measurement:

- Distance Measurement: Traditional methods of distance measurement were often prone to human error and limited in scope. Laser distance meters, however, offer quick, accurate, and long-range measurements. They are especially useful in large-scale projects like construction and topographical surveys.

- Surface Profiling: Lasers can be used to scan surfaces and generate detailed topographic maps. This is crucial in industries like automobile manufacturing, where the slightest unevenness can affect performance.

- Interferometry: This technique uses the interference pattern of two or more laser beams to measure extremely small displacements, refractive index changes, and surface irregularities. It’s widely employed in optical research and has been fundamental in understanding the behavior of light.

While lasers brought in a wave of non-contact measurement possibilities, they are just a part of the bigger metrological revolution.

Precision Instruments: Micrometers, Calipers, and More

With the industrial revolution, there arose a need for more precise manufacturing and assembly processes. This led to the invention of instruments like micrometers and calipers, which brought about an unprecedented level of precision.

- Micrometers: These are designed to measure tiny distances, typically in the range of thousandths of a millimeter. Their precision has made them indispensable in mechanical engineering and machining processes.

- Vernier Calipers: While they’ve existed in some form for centuries, modern vernier calipers allow for accurate measurements of both the internal and external dimensions of an object, offering versatility in various industries.

- Gauge Blocks: Often used in conjunction with micrometers, these are precision-made blocks of metal or ceramic that establish a standard of measurement, allowing for consistent and precise measurements across different scenarios.

However, with the dawn of the digital age, there was a need for even more sophisticated tools.

Software and Computerization: A New Dimension in Metrology

The inclusion of software in metrology took precision to a whole new level. Computers can process vast amounts of data quickly, identify patterns, and generate detailed reports – something human observers might struggle with.

- Computer-Aided Design (CAD): Before the actual manufacturing or building process begins, CAD software allows professionals to create detailed, 3D models of their projects. These can be measured, modified, and optimized, ensuring every aspect is perfect before the physical creation process begins.

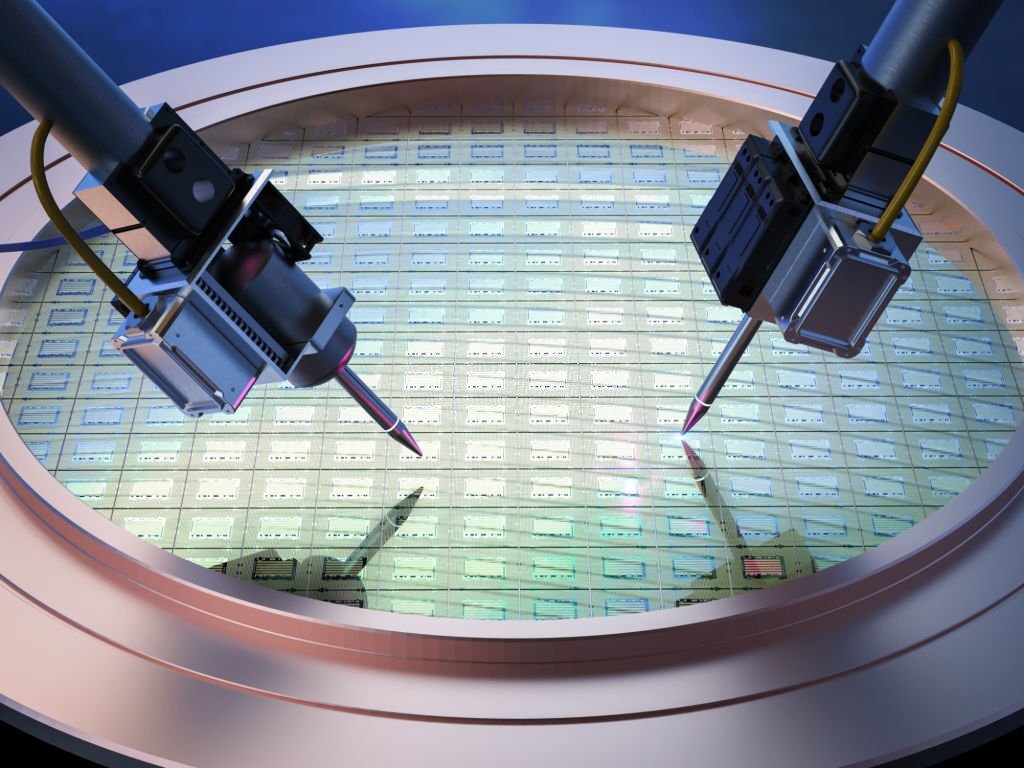

- Coordinate Measuring Machines (CMM): These machines, often used in manufacturing, combine physical probes with sophisticated software to take precise measurements of complex objects. The software can then compare the object’s measurements to its intended design, ensuring it meets the required specifications.

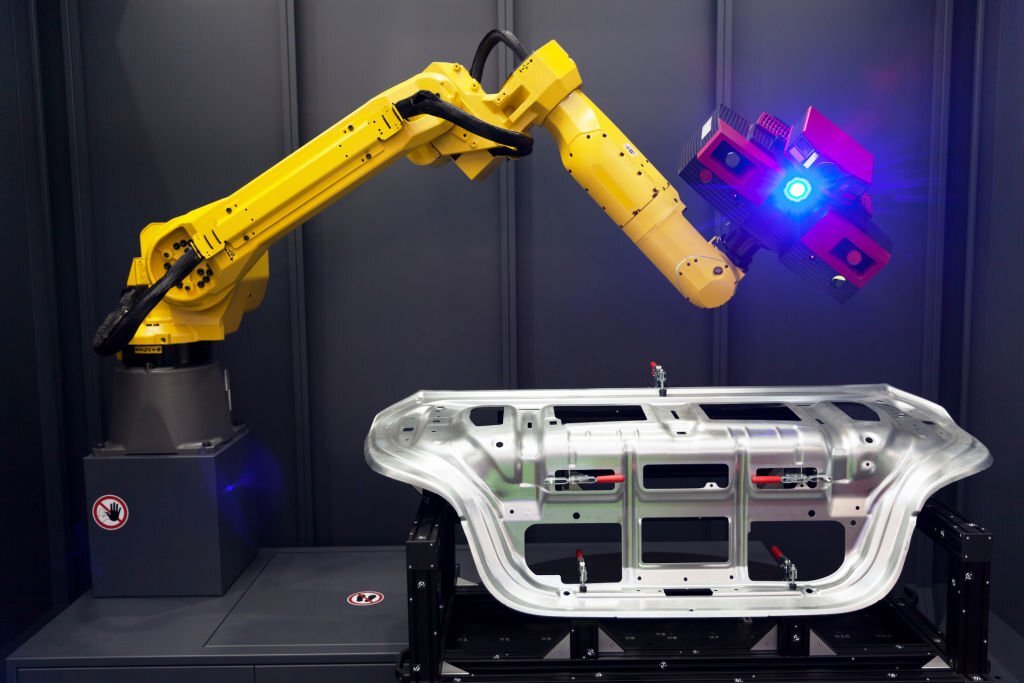

- 3D Scanners: These devices capture the exact shape and size of physical objects, converting them into digital 3D replicas. Once an object is in digital form, its measurements can be analyzed, altered, and even perfected without having to touch the physical object.

In conclusion, the world of metrology has witnessed a remarkable transformation over the years. From the simple rulers of yore to today’s cutting-edge lasers and software, each advancement has been a leap toward greater accuracy, precision, and understanding of the world around us. As technology continues to evolve, so too will our measurement tools, ushering in an era where perhaps even the unimaginable will become measurable.