The dawn of 3D printing has ushered in a revolution that has reshaped the manufacturing industry. A driving force behind this transformation is the meticulous integration of metrology – the science of measurement. Together, these two fields are setting new benchmarks in innovation, efficiency, and quality control. This article explores how accurate measurements ensure that what’s conceived digitally flawlessly takes shape in the real world.

3D Printing: Turning Digital Visions into Physical Realities

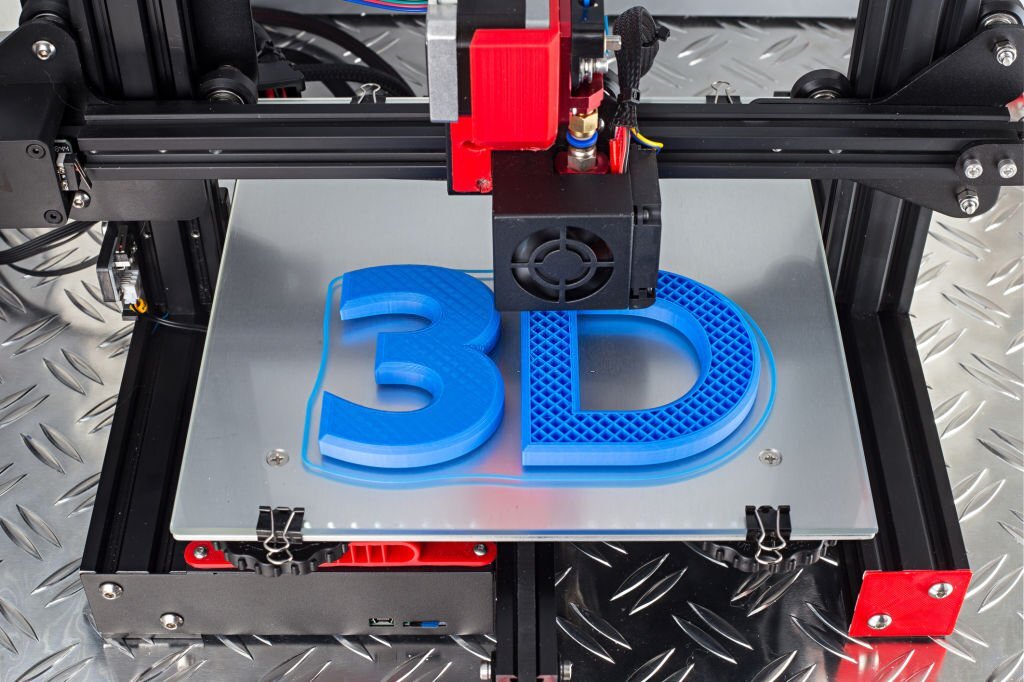

3D printing, also known as additive manufacturing, is a process that allows for the creation of three-dimensional objects from digital files. Using specialized printers, a product is constructed layer by layer, transforming a computerized concept into a tangible object. This technology has far-reaching implications for various industries, including automotive, healthcare, aerospace, and more.

But what sets 3D printing apart isn’t just its ability to manufacture complex designs but its collaboration with metrology. Without precise measurements, the digitally designed object might not align with the physical manifestation, leading to inconsistencies and inefficiencies.

The Marriage of Design and Measurement

The intricate dance between 3D printing and metrology begins with design. Using sophisticated software, designers create intricate 3D models, defining every contour, angle, and surface. This virtual model becomes the blueprint for the physical product.

However, the transformation from digital to physical isn’t straightforward. Any discrepancy in the measurements can lead to significant issues in the final product. This is where metrology plays a crucial role.

Metrology ensures that the measurements used in the 3D design align perfectly with the actual printing process. From the dimensions of the layers to the materials used, every aspect is measured, monitored, and controlled. The result is a product that’s an exact replica of the digital conception.

The Real-World Impact: Precision, Efficiency, and Innovation

The partnership of 3D printing and metrology isn’t just a technical marvel; it has real-world implications that are reshaping how industries operate.

Precision

The most apparent advantage is precision. With metrology’s rigorous standards, 3D printing can achieve accuracy down to the micrometer. This level of precision is vital for industries such as aerospace and healthcare, where even a minor discrepancy can lead to catastrophic failures.

Efficiency

With the integration of metrology, 3D printing can achieve an unprecedented level of efficiency. The digital design, combined with precise measurements, ensures that the printing process is streamlined and accurate. It minimizes waste and reduces the need for extensive testing and adjustments, saving both time and resources.

Innovation

Perhaps the most profound impact of the 3D printing and metrology partnership is on innovation. The ability to translate complex digital designs into physical products without loss of accuracy has opened new frontiers in product development. Engineers and designers can experiment with intricate structures, pushing the boundaries of what’s possible.

The Future: An Ever-Evolving Collaboration

3D printing and metrology are not static fields. Both are continually evolving, driven by technological advancements, research, and the ever-growing demands of various industries.

As 3D printing technology becomes more sophisticated, the role of metrology will only expand. New materials, more complex designs, and higher standards of accuracy will require even more precise measurements.

Simultaneously, advancements in metrology will further empower 3D printing. New techniques, tools, and methodologies in measurement will lead to even more accurate, efficient, and innovative manufacturing processes.

Conclusion

The collaboration between 3D printing and metrology is a defining feature of modern manufacturing. It’s a partnership that embodies the synergy between design and reality, imagination and manifestation.

As we continue to explore the potential of 3D printing, the role of metrology in ensuring accuracy and efficiency will remain pivotal. Together, these two fields are not only shaping the products of today but also laying the foundation for the innovations of tomorrow.

Whether you’re a professional in the industry, a student of technology, or simply intrigued by the marvels of modern manufacturing, the fusion of 3D printing and metrology is a testament to human ingenuity and the boundless potential of collaborative innovation.